We at ATR are tank inspectors first. Our staff includes API-653 Certified Inspectors,

Mechanical Engineers and Material’s Specialists. Over the years we have spent countless

hours inside of tanks. We are the first to recognize that some tanks must be taken

out-of-service for repair, modification and upgrades. But we ask the question...

”If the tank only needs an inspection, why not choose robotics?”

Here are some items to consider:

- Safety: robotic tank inspection is inherently safer than manned entry. Year after year OSHA lists confined space entry as one of the most hazardous industrial activities. Not to mention the exposure to VOC’s and hazardous chemicals to employees and contractors. In short, robotics reduces your At Risk Hours and provides for a safer plant environment.

- Downtime: Tanks are the lifeblood of an industrial facility. They store your fuel. The store your raw material. They store your inventory... sometimes millions of dollars of product. Keeping tanks on-line and in-service allows you to run you facility effectively without disruption or loss of throughput. Mission critical tanks are excellent candidates for robotic inspection in all industries.

- Cost: The cost to empty and clean storage tanks increases every year. The cost of waste disposal alone can run into the ten’s if not hundred’s of thousands of dollars. ATR’s robotic inspection is fast, economical, cost effective, and will save you an astounding amount of money.

- Tank Management: Robotics can play an integral part of an overall tank management program. Organizations that own/operate large tank fleets understand the value of information that can be used to help manage the lifecycle of tank assets. Simply being able to study and prioritize tanks while they remain in-service adds reliability and reduces overall fleet risk. Methods such as Risk Based Inspection (API 580) will benefit greatly from data generated via robotic inspection. Robotic tank inspection will increase your overall reliability, safety and will reduce corporate wide risk.

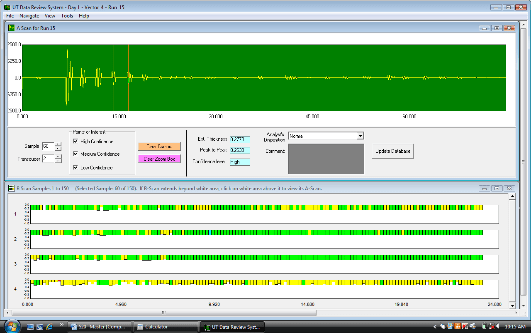

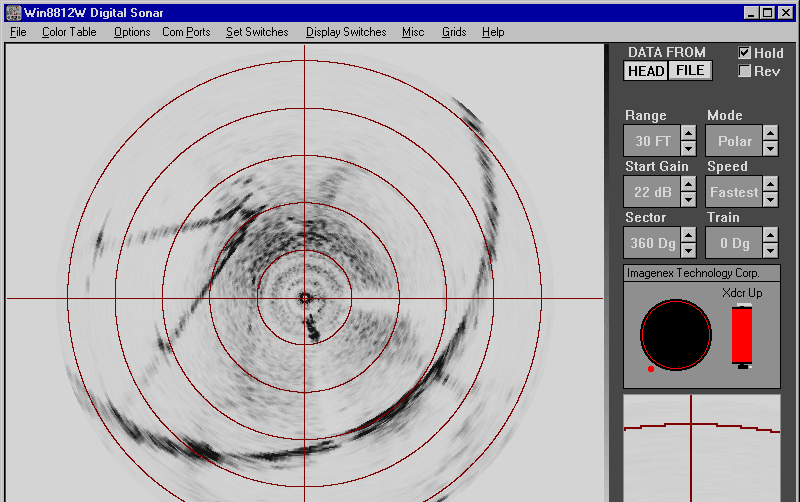

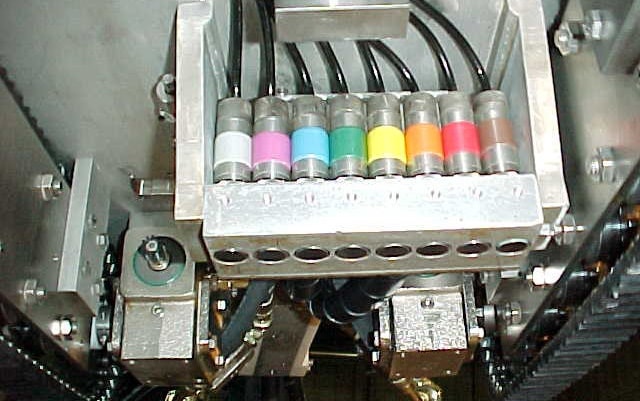

- Quality: ATR’s robotic inspection utilizes state-of-the-art ultrasonics to effectively inspect your storage tank. Literally ten’s of thousands of data points are collected from each tank. Far more than can be collected while the tank is out-of-service. This large amount of high quality data insures the accurate calculation of corrosion rates and remaining life estimates that can be used for planning future inspection and possible repair.